|

The culture of warehouse management

Technology is just one element of effective warehouse management.

by

What are you trying to accomplish through your warehouse operations? That is, what is the goal of effective warehouse management? We believe that it is to minimize the costs of both maintaining inventory in your facility and filling customer orders.

There is no doubt that advances in technology are helping distributors achieve this goal. From December 2001 through November 2002, we helped calculate the cost of carrying inventory for more than 50 distributors. These firms sold many different types of products and were located in various geographic regions. The cost of carrying inventory in a warehouse that used bar coding for receiving, picking and counting inventory was on average 27.6 percent lower than a warehouse that manually performed these functions.

Bar coding provides these firms with many benefits including:

• Confirmation that the correct items are picked for orders and stock receipts are put away in the proper location.

• Elimination of many data entry errors.

• The integration of cycle counting (for example, ongoing verification of computer stock balances) into normal material handling procedures.

• Increased productivity through elimination of paperwork.

But can we attribute all of the carrying cost savings to the implementation of bar coding equipment or other technology? Probably not. Though bar code equipment offers many benefits, there are some things that technology just cannot do:

• Organize your warehouse to minimize the cost of filling orders.

• Ensure that all material movement is properly recorded.

• Protect you from inventory losses due to theft, breakage, etc.

It’s interesting that distributors that successfully implemented bar coding technology overcame these (and other) obstacles. How?

In addition to adopting new technologies, these firms have implemented a culture of effective warehouse management. This article examines a few elements of this culture.

Store products to minimize the cost of filling orders Store products to minimize the cost of filling orders

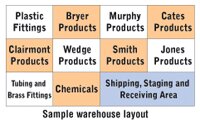

Most distributors still stock similar products next to each other. Each area of the warehouse is reserved for a specific product line. Look at the sample warehouse layout shown here.

This arrangement makes it easy to find any product. All of the Cates products are located in one area and the plastic fittings in another. But this arrangement causes productivity of the order pickers to suffer. Why?

Each of the 10 product lines in our sample warehouse contain very popular products, items with moderate customer demand and slow-moving inventory. To fill an order for a popular plastic fitting, a picker has to go to the far back corner of the warehouse. If he or she does this several times an hour, “travel” time may in fact exceed the amount of time pickers spend actually picking orders.

At the same time, slow-moving chemicals as well as Smith and Jones products are stored near the shipping, staging and receiving area. Pickers constantly walk past them to get to the fast-moving products in other lines.

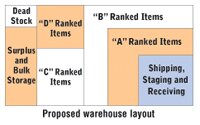

Your pickers will be much more productive if you locate the products that are picked most often (regardless of their product line) in the most accessible bin locations. We refer to these products as “A” ranked products. The bins for “A” ranked products are typically located close to the shipping and staging area as shown in the proposed layout (below).

In addition to being physically close to where material will be shipped, bins for “A” rank products are accessible in other ways as well. Pickers can easily reach into these locations to fill orders, for example, when you utilize knee-level to eye-level shelves and ground-level pallet locations. In addition to being physically close to where material will be shipped, bins for “A” rank products are accessible in other ways as well. Pickers can easily reach into these locations to fill orders, for example, when you utilize knee-level to eye-level shelves and ground-level pallet locations.

To determine what products fall into the “A” rank category, we sort all products in a warehouse in descending order based on the number of times someone requested the product (regardless of the quantity ordered). This measurement is typically referred to as “hits.” Here is an example of a hits ranking:

| Product |

Hits |

Accumulated hits |

Accum % |

Rank |

| 46916 |

523 |

523 |

25.97% |

A |

| 78691 |

400 |

923 |

45.83% |

A |

| 78792 |

389 |

1312 |

65.14% |

A |

| 120303 |

198 |

1510 |

74.98% |

A |

| 91 |

103 |

1613 |

80.09% |

B |

| 122378 |

62 |

1675 |

83.17% |

B |

| 120412 |

61 |

1736 |

86.20% |

B |

| 78893 |

60 |

1796 |

89.18% |

B |

| 400808 |

54 |

1850 |

91.86% |

B |

| 785723 |

46 |

1896 |

94.14% |

B |

| 78588 |

26 |

1922 |

95.43% |

C |

| 78590 |

22 |

1944 |

96.52% |

C |

| 785023 |

18 |

1962 |

97.42% |

C |

| 234340 |

15 |

1977 |

98.16% |

C |

| 78326 |

10 |

1987 |

98.66% |

C |

| 11234 |

9 |

1996 |

99.11% |

D |

| 78719 |

8 |

2004 |

99.50% |

D |

| 43212 |

6 |

2010 |

99.80% |

D |

| 109223 |

4 |

2014 |

100.00% |

D |

| 61160 |

0 |

2014 |

100.00% |

X |

| 78589 |

0 |

2014 |

100.00% |

X |

| 400300 |

0 |

2014 |

100.00% |

X |

| 401306 |

0 |

2014 |

100.00% |

X |

| 78523 |

0 |

2014 |

100.00% |

X |

| 120303 |

0 |

2014 |

100.00% |

X |

| Total |

2014 |

|

|

|

•· “A” ranked products account for up to 80% of total hits

• “B” ranked products account for the next 15% of hits

• “C” ranked products account for the next 4% of hits

• “D” ranked products account for the last 1% of hits

• “X” ranked products are dead stock and have not been requested

Notice in the diagram above that products with fewer hits are stored further away from the staging and shipping area. Considering the inventory of the 50 distributors we’ve worked with in the past 12 months, typically only 10 percent to 13 percent of stocked products account for 80 percent of hits, and less than 50 percent of stocked items account for 95 percent of hits. The 50 percent of the stocked products that account for only 5 percent of hits can be stored in the least accessible locations.

The result: A majority of your picking activity is confined to a limited area of your warehouse. There is less traveling and more picking!

Distributors trying to achieve the best possible warehouse operations will supplement this general stocking policy with a couple of additional rules:

• Stock products near each other if they almost always appear on the same customer orders.

• When assigning product locations, consider the order in which items should be pulled from stock. For example, if heavy items should be placed on the bottom of a pallet, arrange locations so these items are picked first.

Properly record all material movement

If someone removes material from your warehouse without scanning the item or recording the transaction in some other way, the computer’s available quantity will not agree with what is physically available in the warehouse. This results in unexpected stock outs and wasted time as pickers search for the missing material.

In order to achieve effective warehouse management, outline the procedures your employees need to follow for processing every type of material disbursement and receipt. Combine all of the procedures to create your company’s official procedures guide. These procedure guides typically outline how to process the following transactions:

• Normal stock receipts (from previously issued purchase orders and transfers).

• Unexpected stock receipts (the stuff that just shows up on your receiving dock).

• Requisitions - (a request for material to be consumed within your company).

• Emergency requisitions.

• Sales: (Orders to be delivered; Orders to be picked up; Cash sales; Direct shipments; Orders for non-stock products).

• Transfers to other warehouses or facilities.

• Assembly orders.

• Bin-to-bin transfers within your warehouse.

• Returns of stock material.

• Returns of non-stock material.

• Returns of damaged material.

• Returns to your supplier.

• Adjustments to on-hand quantities (Who is allowed to approve adjustments? Under what circumstances?)

• Scrapping and writing-off stock.

You probably can add to this list. It is vital that every employee knows how to properly record each type of material movement. In companies that practice effective warehouse management there are two ways to do things: The approved way and the wrong way!

Protect inventory from theft and breakage

Many retailers have implemented bar coding and other state-of-the-art technologies. Yet pilferage and material damage is rampant in the retail industry.

As with locating products and recording material movement, you must implement some “best practice” procedures to ensure that you minimize this costly problem that can increase your costs of doing business while decreasing the productivity of your warehouse employees.

First, take an objective look at your warehouse. Determine if it is possible for an outsider (or even an employee) to remove material from your warehouse without it being invoiced or recorded.

Are doors to the outside left open and unattended? Lock them, install security cameras or install a fence that encloses your inventory.

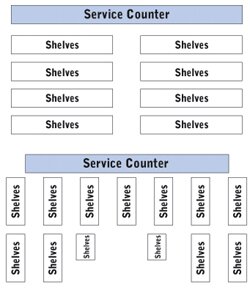

If customers fill their own orders or you have a retail trade area, can someone hide behind a display and hide material? Compare the two counter area layouts shown here.

In the first layout, someone behind the service counter cannot see all of the activity occurring in the aisles between the shelving units. It would not be difficult to steal something small that can be hidden in clothing or a small package. The shelf arrangement in the second counter area layout allows anyone behind the service counter to have an unobstructed view of the entire retail area. In the first layout, someone behind the service counter cannot see all of the activity occurring in the aisles between the shelving units. It would not be difficult to steal something small that can be hidden in clothing or a small package. The shelf arrangement in the second counter area layout allows anyone behind the service counter to have an unobstructed view of the entire retail area.

Material breakage can be substantially reduced or even eliminated if you insist that inventory never be left in aisles or in other places where it doesn’t belong. Your stock inventory is valuable. It should never be left lying around. Every piece of every product belongs in its assigned bin location where you can find it and it is protected from damage.

There is no doubt that bar coding and other new technologies will reduce operating costs and represent cost-effective investments for many distributors. But these technical solutions alone cannot help you minimize your total cost of maintaining material in your warehouse and filling orders.

In order to achieve effective warehouse management, you have to combine state-of-the-art technical solutions with “best practice” policies and procedures.

Jon Schreibfeder is president of Effective Inventory Management Inc. in Coppell, Texas, and author of a number of inventory-related books, including Achieving Effective Inventory Management 2nd Edition. Reach Jon by phone at or at .

This article originally appeared in the January 2003 issue of Progressive Distributor. Copyright 2003.

back to top back to e-business archives

|