|

Plugging sales leaks

A case study in quotation management

by Steve Deist and Holt Cason

In today’s stagnant economy, distributors must pull out all the stops to grow sales. Finding new business is essential, but it is equally critical to respond effectively to the business that finds you. For many distributors, such business arrives in the form of a request for quotation (RFQ). This case study shows how one distributor increased sales, improved customer service and reduced costs by significantly enhancing its quotation process management.

The situation

Purchased Parts Group Inc. (PPGI) is a distributor of industrial fasteners to automotive and other OEM manufacturers. A large portion of its new business generation comes from responding to RFQs. These RFQs could be as simple as a price quote for a fixed quantity of a single standard part. However, they are often quite complex, with hundreds of line items, custom parts with detailed specifications and engineering drawings, multiple delivery dates and variable quantities.

The RFQ process is resource intensive. It involves obtaining initial requirements from the customer, sourcing the parts from PPGI’s suppliers (which involves identifying qualified vendors and managing PPGI’s own RFQ process), and collecting all the information into a final bid package.

In addition to the new business, many of PPGI’s existing customer contracts call for annual cost reductions, which PPGI can only achieve through cost reductions from its suppliers. This “re-sourcing” process is similar to the RFQ process in terms of its workflow and effort required.

The challenges

PPGI recognized that improvements in its sourcing and RFQ process could potentially offer a lower cost to respond, a higher close rate, improved margins and, most importantly, better service to its customers. In November of 2001, it asked the Indian River Consulting Group (IRCG) to analyze the situation and recommend improvements.

In any re-engineering project, the first step is to separate fact from myth. IRCG visited each PPGI location and walked through the steps with the people who do them day in and day out, and made the following general observations:

• At PPGI, quoting and sourcing were a craft, not a process. There was no standard, repeatable, measurable procedure that could be managed or improved. Everyone did it his or her own way and the quality of the results was totally dependent on the skills of the individuals involved. Fortunately, PPGI had a small cadre of experienced and capable bidders who produced outstanding results from the tools they had. Obviously, however, losing a single member of this team would have been devastating.

• Quotes came from every direction. A number of different people within PPGI produced quotations for customers. In addition to the designated bidders, outside salespeople, customer service representatives and purchasing agents routinely received and responded to RFQs. While this strong customer service attitude was commendable, it ultimately reduced the service level that PPGI provided customers. Salespeople were sometimes unaware of significant quotes in process when calling on their accounts. Quotes often took longer than necessary because employees could not locate similar past quotes and the wrong people often worked on a task (such as salespeople negotiating with suppliers). In addition, it was highly likely that some of PPGI’s customers consciously price-shopped within PPGI, asking two or three different PPGI associates for a quote and then selecting the best price.

• There was no summary reporting or ability to proactively manage the business pipeline. At any point in time, PPGI had no way of knowing the total value of opportunities in play or the rate at which they were being closed. Upper management could not make sound decisions about deploying limited resources because they didn’t know the types of quotes that PPGI was most likely to win. They couldn’t identify “looky loo” customers who always asked for quotes but never gave their business to PPGI.

• PPGI had islands of information. Because of the limited capabilities of PPGI’s business system, quotation and sourcing was primarily paper based. People recorded quotes on handwritten notes or in different individual spreadsheets. Key information, such as customer requirements and supplier conditions, was maintained in paper folders. This made it difficult to quickly find information or know who was working on what. More significantly, it greatly increased the opportunity for errors. When supplier offerings and customer requirements didn’t match, PPGI was caught in the middle and often had to pay to correct the variance.

The solution

The first step in designing a solution was identifying and prioritizing the characteristics of an ideal quotation process. Prioritization forced the team to think clearly about its requirements and confront the trade-offs inherent in any standardized process. The team agreed on the following basic principles:

1) It was imperative to have a centralized, easily accessible view of all quotation activity occurring in the company. Without this, PPGI could not provide timely support to its sales force or make systematic improvements in the process.

2) The quotation process must remain simple and flexible. A complicated process would be difficult to learn and would hinder adoption. PPGI also didn’t want to dilute the effectiveness of the quotation staff by making them follow mindless procedures or spend hours typing into a computer.

3) Keep it cheap. Regardless of the payback potential, PPGI simply didn’t have the financial freedom to spend hundreds of thousands of dollars for process re-engineering or automation.

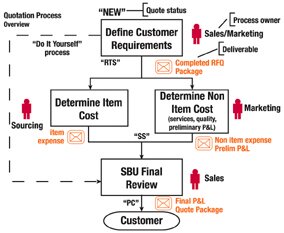

With these principles in mind, the team proceeded to create a clear flow chart of the ideal process. Although it may look basic, a flow chart is extremely important. By getting the process down on paper, it proved that everyone had a shared vision of the process and that all major exception conditions were covered. The team found that the best way to organize the documents was to create an overall process flow chart that fit on a single page. It then created more detailed flows for each major process. In some cases, a third level of detail was required. This methodology allowed anyone to quickly see the whole picture and then drill down into specific areas of interest.

In addition to showing how the work was to occur, the process flow showed who was responsible for each key task and the “deliverable” or output from it. The team wanted no confusion as to whether a task was truly done or not. The team studiously avoided the temptation of omitting these “owners” and “deliverables,” or being ambiguous about them.

The clarity of the documents was demonstrated by the passion they generated in review meetings. After many discussions and several revisions, management approved the process and the team obtained a commitment from all owners. Not everyone was happy about every aspect of the proposed process, but they were clear about their new roles and responsibilities.

Careful readers will notice the potential for conflict between the team’s first guiding principle (a consistent, centralized view of all quotation activity) and its second (keep it simple and flexible). Clearly, tracking quotation data as painlessly as possible requires some level of automation.

To keep the cost low and ensure that the system could be supported internally, the team elected to create a “Quote Tracker” system using Microsoft Access. IRCG consultants developed the initial version of the system because they had extensive knowledge of best practices and the technical expertise to quickly create a working prototype. However, to foster ownership and reduce costs, they transitioned the project to PPGI’s IT staff as the requirements were finalized and PPGI employees became more comfortable with the software. They chose Access because it offers an open architecture that readily integrates with most databases, is relatively low cost, is easy for both users and programmers to learn, and has a large pool of experienced programmers available. In Access, user screens can be created graphically, using simple drag-and-drop tools. However, the Quote Tracker also employs some Visual Basic language programming.

Basically, the Quote Tracker is a database that relates lines on customer RFQs to lines on supplier bids. It also keeps track of the status of RFQs, identifies the next action and who is currently responsible for taking that action.

Based on the flow chart for the process, the team designed the following functions into Quote Tracker:

• Quickly log a new request for quote. The key to meaningful pipeline management is capturing all activity. To encourage data capture, the team limited the RFQ logging process to entering a few data fields. By using an internal database of customers and salespeople, the team made the automated quote creation even simpler than its paper-based counterpart. This helped speed adoption and gave the users a positive initial experience with the system.

• Automatically notify support staff. Creating and updating quotes triggers notifications to those needed to help close the business. This includes product specialists, quotation staff, purchasing personnel and salespeople.

• Pipeline analysis. By tracking the progress of each quote as it moves through each process gate, Quote Tracker provides managers with the information they need to prioritize, expedite and follow up. They can use the aggregate data to calculate close rates, distinguish real customers from those who are just using PPGI as the third bidder, and make other management decisions.

• Automatically tie supplier RFQs to customer quotes. As suppliers respond with their own quotes, Quote Tracker enables PPGI to quickly identify the best price and automatically assign the supplier’s response to the customer’s quote. This saves significant time and, more importantly, reduces PPGI’s risk of being caught in the middle between a supplier commitment and a customer promise.

• Automatic printing and e-mail. Quote Tracker transmits quotes to customers and RFQs to suppliers direct from the database. This saves considerable time and expense in printing, copying, faxing and filing.

There was no shortage of ideas for enhancing Quote Tracker. Digitizing drawings, call tracking, automated bid package creation and labor utilization rates were all considered. At the end of the day, however, the best is the enemy of the good. Quote Tracker had the critical functions required to meet the project objectives, while remaining relatively inexpensive and simple to learn.

The results

Before Quote Tracker, PPGI didn’t have reliable statistics on quotation performance, so before and after comparisons are difficult. However, in the year since Quote Tracker went live, processing time for incoming RFQs decreased from an average of 3 days to 2.5 hours. The kill rate for new business increased substantially because of this improved responsiveness and because PPGI now has the information to identify the most fruitful opportunities. Although it deals with a greater volume of quotations, the sourcing organization shrunk by 25 percent while service levels improved.

Other intangible benefits include:

• The automation leaves little room for error; internal checks and balances match requested items with quoted items. When discrepancies occur, the transaction trail makes it far easier to research and resolve them.

• Price and quotation lookups are faster and easier. Even field personnel can review a part to determine if it was quoted previously. Since a single line can require several man-days in total quotation effort, the ability to reuse recent quotes is extremely valuable.

• The entire sourcing team has become more disciplined. Costly and dangerous process shortcuts are harder to take and more visible to management.

• Comparison between suppliers is far easier than before, with all information displayed on a single screen.

• Everyone speaks the same language. Quote information is recorded and maintained in a standard format. Work can be easily reassigned to balance workload and take advantage of individual specialization. Executives, managers, salespeople and the sourcing department all share a common view of quote activity.

Lessons learned

This project shows that targeted, well-designed process improvements, plus some basic automation can greatly improve quotation efficiency and effectiveness. Keeping the project focused on a specific process enabled the team to avoid scope creep, keep costs low and meet deadlines.

Outside experts helped assess the current process, recommended specific improvements based on best practices, facilitated the new process design and created the initial automation tools, but the project was quickly transitioned to internal staff to ensure ownership and reduce development costs.

Naturally, with anything new, there is always resistance to change. The implementation team knew the importance of establishing (and meeting) a firm rollout date. Once introduced, the new sourcing and quotation process rapidly became the norm for conducting business. •

Steve Deist ) is responsible for the Operations Practice at Indian River Consulting Group. IRCG is an experienced-based firm specializing in distribution. Contact him at , or visit www.ircg.com for more information.

Holt Cason ) is vice president of supply chain management, for Purchased Parts Group Inc., an international distributor of production fasteners and other Class C components. Contact him at , or visit www.purchasedparts.com.

back to top back to e-business archives

|