Genuine ergonomic hand tools reduce

worker injury rates, but buyers beware

by Robert Rozzi, Bahco Tools Inc.

The term "ergonomic tools" is still relatively new. Since 1995 such tools have received broad attention. But buyers beware. There are a lot of unsubstantiated ergonomic tools on the market that claim benefits to end-users but are just merely all show and no go. Before selecting your next hand tool, take the time to learn about the manufacturer's claim to the benefits and demand to see proof, in writing, if necessary.

While any tool can carry an ergonomic label, tools that undergo a specialized ergonomic design process take into consideration cumulative trauma disorders (CTD) and repetitive strain injuries (RSI). The design process requires the tool to be thoroughly researched and tested in order to validate the real benefit they provide to the user.

True ergonomic design results are quantified

Some manufacturers use the term ergonomic to imply quality. The product may be dressed in a nice package and labeled ergonomic even though the tool does nothing to remedy RSIs. For instance, cushioned grips on hand tools are commonly perceived as being ergonomic, even though the designers cite no research explaining how the padding protects the hand.

It doesnt take much time to research a manufacturers claim to whether their product is actually ergonomic or just a fake. Simply go online or call them. More importantly, learn what others, including independent research labs are saying about the product. Besides, if youre purchasing a substantial amount of tools for your workers, you can save literally thousands of dollars in health claims by buying a true quality ergonomic product. The Occupational Safety & Health Administration believes that companies who comply to ergonomic programs will reduce the number of repetitive motion and back injury claims by 250,000 annually.

Most important, true ergonomic hand tool manufacturers use professional workers to test the prototypes. Researchers evaluate the subject by electromyography to gauge muscle tension and a goniometer to track the users hands. Prototypes are revised and tested again by more users to refine function and comfort. Pilot production tools are evaluated once again before the tool enters the market. For instance, a five-year follow-up on all Bahco hand tools verifies that the tool is being used properly to prevent injuries. The result of the process is an ergonomic tool with a pedigree of research, and one that makes a difference in worker injury statistics and productivity.

Recognize a genuinely ergonomic hand tool

Most genuine ergonomic tools feature rounded areas and protective shields that reduce the risk of immediate direct injuries, such as cuts and bruises. For example, properly designed pliers should have no unnecessary sharp edges, even around the jaws. Ergonomic tools also should minimize the cumulative wear and tear on skin that leads to abrasions, blisters and calluses. For instance, screwdrivers that have a hard core should be surrounded with a soft thermoplastic gripping surface to protect skin and preserve the grip. The soft gripping surface improves traction and prevents rubbing. Safe design should also ensure that tools dont pinch or snag hands between closing parts. Ergonomic slip-joint pliers, for example, have handles that remain open even when the jaws are fully shut to keep from pinching palms.

Again, ask to see research, design protocols, and field tests that support ergonomic claims. Get it in writing. It may take a while to verify a hand tools ergonomic claims. However, it is definitely worth your time, especially for project managers who have hundreds of workers using these tools daily for extended periods of time.

Run your own comparative trials

Survey employees for feedback. This step is also worth your time and effort because youll see clear differences in the response. Sample tools should always be trial tested in actual work conditions by everyday users to see if the tools prove out to be truly ergonomic.

Evaluate the ergonomic esperience of the manufacturer

How many true ergonomic products does the vendor really make? If the tooling manufacturer has a proven history in developing genuine ergonomic tools, then chances are they have a hand tool to fit your application.

Conclusion

Remember, dont be fooled by products that just look good and have no real ergonomic validation. Always try to evaluate the actual improvements that the ergonomic tools provide, the real differences they make to the user.

Documented research and disciplined ergonomic design have already led to many advances in worker comfort, safety and productivity. And, the field is still improving. Heres just a glimpse at some of the more recent ergonomic developments:

- Adjustable springs in wire cutters and pliers minimize resistance in the handles at the moment wires are cut.

- Anti-friction coatings on handsaws help cut wood with approximately 40% less force than is required with uncoated saws.

- V-shaped handle transitions on ergonomic screwdrivers to facilitate intricate product repair using the fingertips.

- Thick, wide handles on adjustable wrenches enable users to apply two to three times the torque available from conventional wrenches and without pain.

- Slip-joint pliers with handles that stay open even when the jaws are fully shut protect against pinching the users palms.

- Files with symmetric handles with large, rounded ends to minimize gripping forces, so that workers dont tire easily.

- Handles feature a slip-guard to prevent accidental skin abrasions.

Genuine ergonomic tools do pay off by reducing the risk of both direct and long-term injury to workers, thus improving overall productivity.

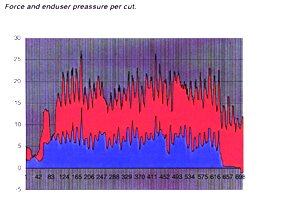

Figure 1 Figure 1

The graph to the left shows the users pressure in kilos per cut in a solid steel bar (maximum peaks are at around 25 kilos). The upper area shows a conventional frame with a horizontal handle. The lower area shows the new ERGO 325. As an average, the 325 cuts the workpiece with approximately 40% less force and also at a slightly shorter time due to the new ergonomic design.

Figure 2 Figure 2

Genuine ergonomic tools have helped to reduce worker injury rates and also improve worker productivity at many industrial plants nationwide. Workers at a high-volume electronic assembly operation, for instance, ended repetitive strain injuries by integrating Rx-Series ERGO wire cutters and pliers into their operations. The new cutters have sharpened cutting blades with rounded edges and rounded grips for better user safety and cutting position. The ergonomic hand tools are from Bahco Tools Inc.

Figure 3 Figure 3

Buyers of industrial duty hand tools should always ask tooling manufacturers for research and design protocols that substantiate ergonomic claims of their tools. For example, ergonomically designed tools like the ERGO® Model 9072 RPC US adjustable wrench from Bahco Tools are validated through an 11-Point scientific testing and review process that includes end-user prototype feedback results. The ergonomic wrench shown here can spread hand loads over broad handles to prevent repetitive strain injuries.

Bahco Tools Inc. is a wholly owned subsidiary of Snap-on, Inc. It is the new name for the Sandvik Saws and Tools Company, which Snap-on acquired in 1999.

Back to top

Back to Web-exclusive articles archives

|